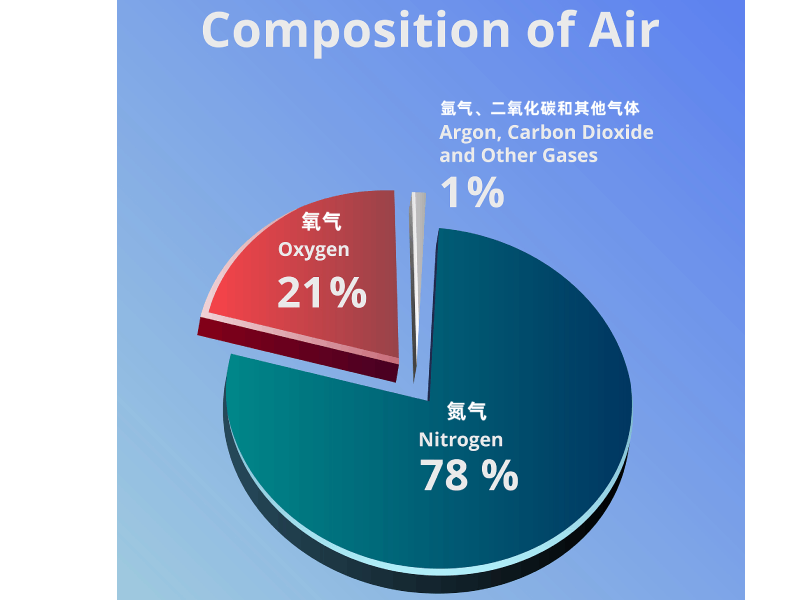

The normal composition of air includes 78.08% nitrogen (N2), 20.95% oxygen (O2), 0.93% argon (Ar), 0.03% carbon dioxide (CO2), and traces of inert gases. However, industrial applications require nitrogen purity levels of at least 95%. This can be achieved using an air compressor and a nitrogen generator, which separates nitrogen and oxygen from compressed air to ensure a continuous, cost-effective, and safe supply of high-purity nitrogen available 24/7.

Nitrogen is an inert gas that does not react easily with other substances. It is widely used as a “protective” gas to replace oxygen in industries like chemical manufacturing, electronics production, food packaging, and oil and gas operations, where preventing fires and explosions is critical.

The Purity Range of Nitrogen

Nitrogen purity requirements vary significantly across industrial applications. Low-purity nitrogen, ranging between 95% and 98%, is suitable for general applications such as fire prevention and inerting. Medium-purity nitrogen, between 98% and 99.5%, is commonly used in food packaging and manufacturing. Ultra-high-purity nitrogen, reaching levels of up to 99.999% or 99.9995%, is essential in sensitive industries like electronics, pharmaceuticals, and aerospace. Selecting the right nitrogen purity ensures efficient processes, product quality, and cost-effectiveness for industrial applications.

What Industries Is Nitrogen Used In?

Nitrogen’s inert properties make it indispensable across numerous industries:

- Chemical Manufacturing: Nitrogen ensures safety by creating an oxygen-free atmosphere, minimizing combustion risks during chemical reactions and storage.

- Electronics Production: High-purity nitrogen prevents oxidation and contamination in the production of semiconductors and electronic components.

- Food and Beverage: Nitrogen replaces oxygen in packaging, extending shelf life and preserving product freshness.

- Oil and Gas Industry: Nitrogen is used for pipeline purging, well stimulation, and ensuring safety during storage and transport.

- Pharmaceuticals: Ultra-high-purity nitrogen maintains sterile environments and ensures stability in the production of sensitive compounds.

These diverse industrial applications of nitrogen demonstrate its importance in maintaining safety, quality, and efficiency across sectors.

How to Get High-Purity Nitrogen Gas?

High-purity nitrogen gas can be obtained using various advanced technologies:

- PSA Nitrogen Generators: Pressure Swing Adsorption systems achieve nitrogen purity levels of up to 99.999% and are widely used across industries.

- Membrane Separation: This method provides nitrogen purity levels between 95% and 99.5%, suitable for food and beverage applications.

- Cryogenic Distillation: This process produces ultra-high-purity nitrogen in large quantities, ideal for industries with extensive nitrogen requirements.

For most businesses, on-site nitrogen generation offers the most cost-effective and reliable solution, ensuring a steady nitrogen supply without relying on external deliveries.

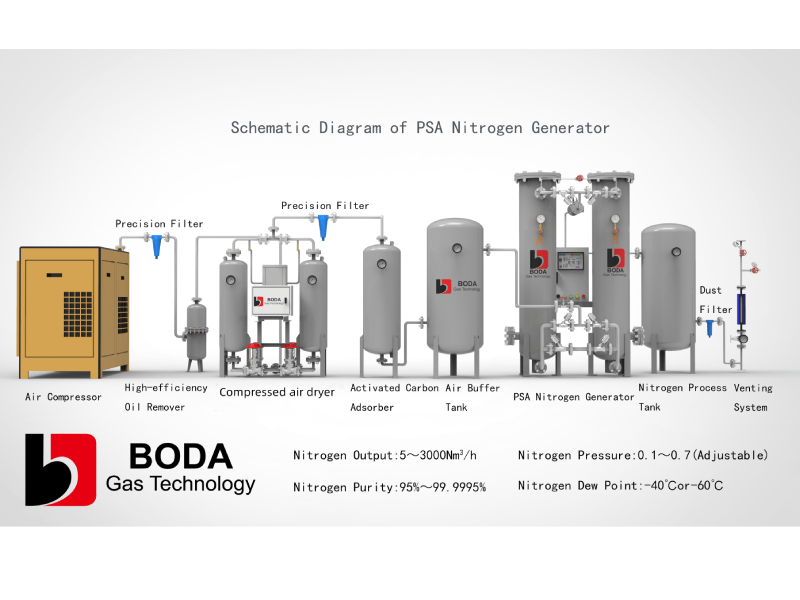

What is PSA for Nitrogen Production?

Pressure Swing Adsorption (PSA) is a widely used nitrogen production technology. It employs carbon molecular sieves to adsorb oxygen and other impurities from compressed air, allowing purified nitrogen to flow through. PSA nitrogen generators are highly efficient, scalable, and capable of producing nitrogen with varying purity levels to meet industrial requirements. This technology is ideal for industries requiring consistent, high-purity nitrogen gas on demand.

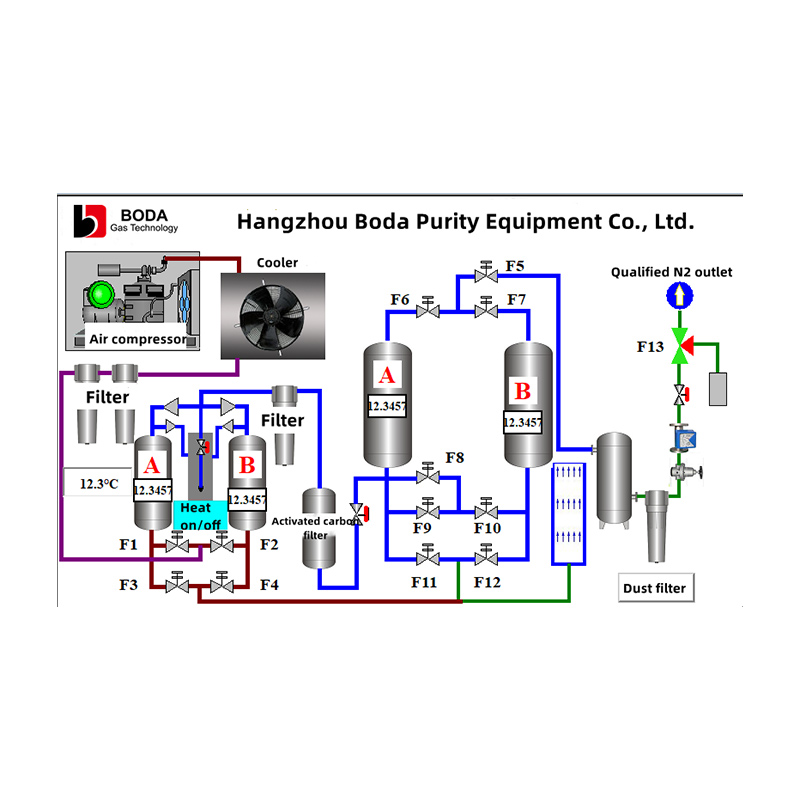

How Does a PSA Nitrogen Plant Work?

A PSA nitrogen plant operates through several key steps:

- Air Compression: Ambient air is compressed using an air compressor to prepare it for processing.

- Air Purification: Filters remove contaminants such as moisture, oil, and particles from the compressed air.

- Oxygen and nitrogen Separation: Oxygen is adsorbed by carbon molecular sieves, while nitrogen passes through as purified gas.

- Delivery: The purified nitrogen gas is stored or delivered directly to its point of use.

This automated process ensures efficiency, reliability, and cost-effectiveness for industries requiring high-purity nitrogen.

Can You Make Nitrogen Gas at Home?

A PSA nitrogen generator or membrane separation system is required to separate nitrogen from ambient air effectively. Small-scale units are available for laboratories and specialized uses, equipment noise can control below 85dB/80dB. For industrial users, on-site nitrogen generation systems offer an efficient, reliable, and scalable solution for continuous nitrogen supply.

Conclusion

Nitrogen’s inertness and versatility make it essential for numerous industries. On-site nitrogen generation is the most efficient and reliable way to meet industrial nitrogen needs.