Working principle

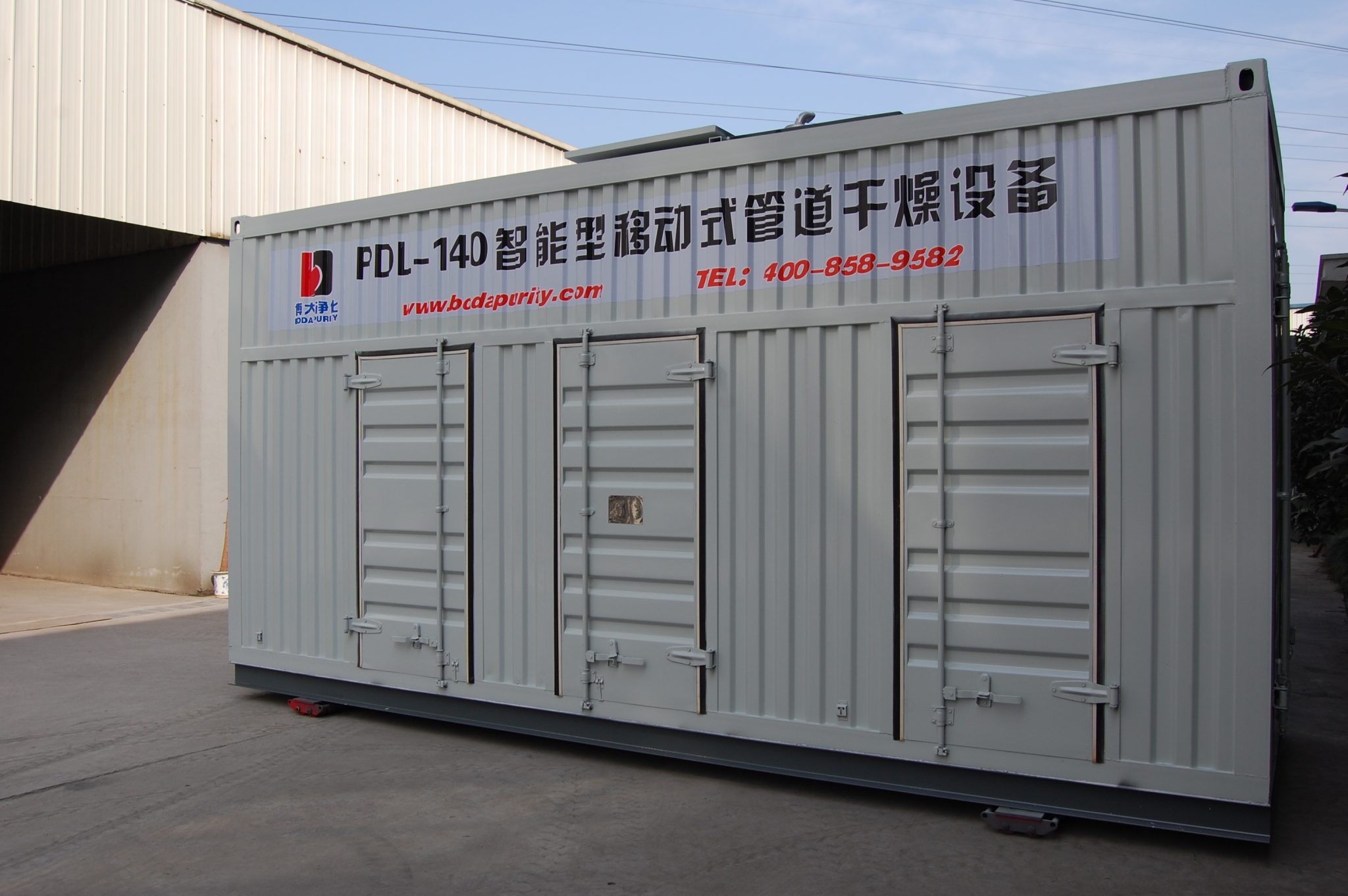

The PDL Series Portable Pipeline Compressed Air Dryer integrates a high-efficiency air-cooled heat exchanger, a high-efficiency oil separator, and a compressed air dryer into a single unit. It features a skid-mounted structure and is equipped with advanced components such as a programmable controller, an online dew point meter, and an intelligent flow meter. The unit is designed with a container-style structure for easy transportation and field use, offering high purification efficiency, ease of operation, and a high level of automation. It is widely used for purging and drying pipelines in the petroleum, natural gas, and industrial chemical industries.

Configuration and Functions

▶Low Regeneration Air Consumption and Energy Use: Features minimal regeneration air consumption and low energy consumption.

▶Stable Dew Point of Finished Air: Ensures a stable dew point for the output air.

▶PLC Control with LCD Display: Uses PLC control with real-time status display on an LCD screen.

▶Online Dew Point Detection, Control, and Alarm: Includes online detection, control, and alarm functions for the dew point of the finished air.

▶Precise Flow Measurement: Accurately displays instantaneous and cumulative compressed air flow.

▶Multiple Fault Alarms and Handling Functions: Equipped with various fault alarms and handling capabilities.

▶Container-Style Structure: Features a container-style design for easy operation, lifting, and transportation.

▶Integrated Power Supply System: Comes with an integrated power supply system for convenient field operation.

▶Portable Dew Point Meter: Includes a portable dew point meter for on-site dew point testing.