Nitrogen and oxygen generators play a widely used and significant role in the food preservation and packaging industry. Ensuring food quality and safety while extending its shelf life is crucial in food preservation and packaging. With advancements in technology, the application of nitrogen and oxygen generators has become an indispensable technical means in the modern food preservation and packaging industry.

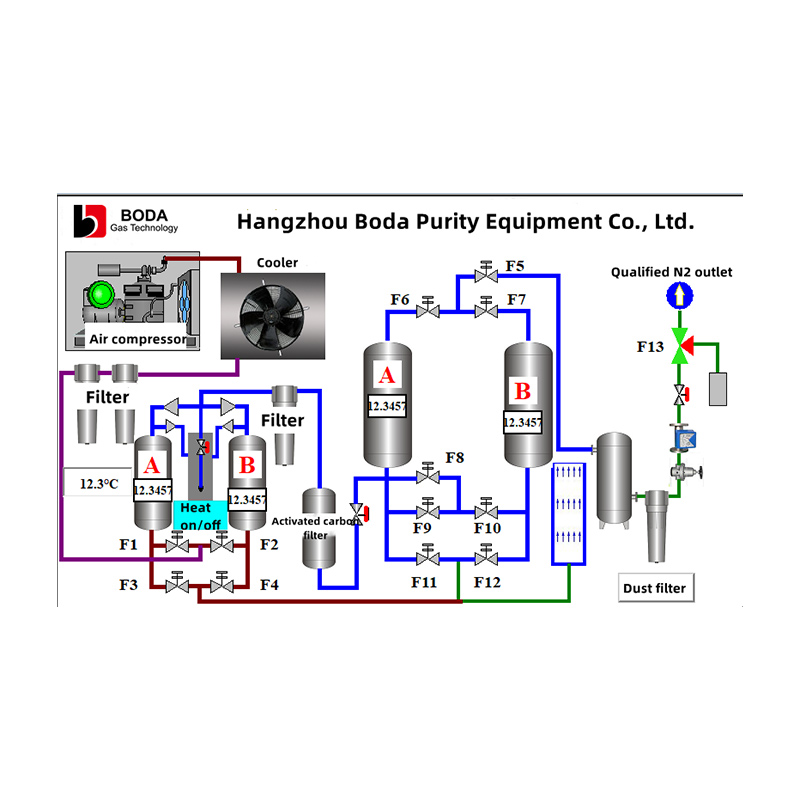

The application of nitrogen generators in the food packaging industry primarily focuses on several aspects. Firstly, high-purity nitrogen gas is separated from the air through physical methods, providing a non-oxygen environment for food, thereby effectively slowing down oxidation and decay processes, significantly extending the shelf life of food. This non-oxygen environment can prevent the growth of bacteria and viruses in food, reduce the oxygen content in food, and further ensure food safety and freshness. According to statistical data, the shelf life of food packaged with nitrogen technology can be extended by more than 40%.

Secondly, nitrogen packaging not only effectively extends the shelf life of food but also maintains the color and taste of food. During storage and transportation, nitrogen can effectively prevent food from being contaminated and damaged by the external environment, keeping the original flavor and nutritional value of food within its shelf life. In addition, nitrogen can also improve the nutritional value of food. For example, in the food production process, by precisely controlling the purity and flow rate of nitrogen, food can fully absorb nutrients, enhancing the nutritional value of food.

Furthermore, the application of nitrogen generators not only improves food quality and safety but also brings significant economic benefits to companies. Enterprises using nitrogen preservation technology can reduce product loss rates. According to statistics, the product loss rate of enterprises using nitrogen preservation technology can be reduced by about 20%, significantly reducing enterprise costs. At the same time, nitrogen generators are easy to operate and can quickly produce high-purity nitrogen gas to meet the needs of food production, improving production efficiency.

Lastly, customized PSA nitrogen generators can provide appropriate nitrogen purity and supply methods based on the specific needs of food companies, ensuring food quality and safety. By precisely controlling the purity and flow rate of nitrogen, companies can ensure stability and consistency during production, reducing product loss and unqualified rates. At the same time, customized PSA nitrogen generators can also adapt to different scales of gas consumption, ensuring that equipment runs under optimal conditions and avoiding resource waste.

In summary, nitrogen and oxygen generators have many advantages in the application of food preservation and packaging industry. From ensuring food quality and safety, improving food taste and nutritional value, to bringing economic benefits and meeting different production needs, these advantages jointly promote the development of food preservation technology and meet consumers’ high requirements for food quality.