BXO-20 93±3% oxygen generator exported to Singapore

12 sets of oxygen generator equipment are in the process of export and shipment. The export flow rate of the oxygen generator equipment is 20 cubic meters per hour. The purity is 93±3%. The export pressure is 15 MPa (adjustable).

The PSA oxygen generator is a device that uses pressure swing adsorption technology to produce oxygen. The following is a detailed introduction to it:

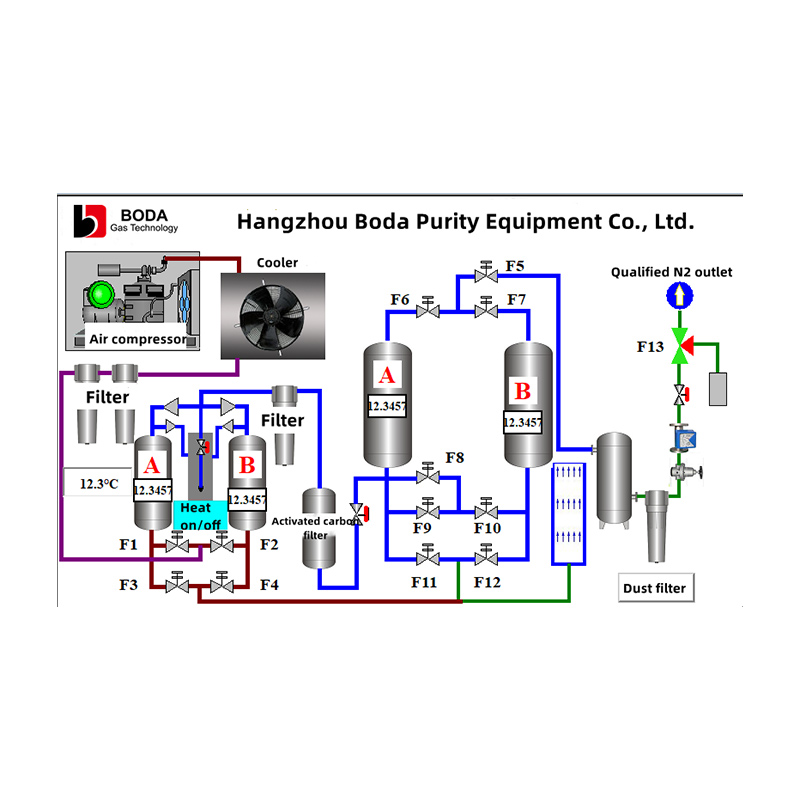

Working Principle:

Utilize the difference in adsorption capacity of adsorbents such as zeolite molecular sieves for different gas components in the air. Under normal temperatures and low pressure, through the processes of pressurized adsorption and depressurized desorption, high-purity oxygen is separated from the air. When air passes through the adsorbent under pressure, nitrogen, and other substances are adsorbed in large quantities by the adsorbent, while oxygen is enriched in the gas phase to form finished oxygen. Then, through decompression, the adsorbent desorbs the adsorbed nitrogen and other impurities to realize the regeneration of the adsorbent. Usually, two adsorption towers are set in the system. One tower adsorbs and produces oxygen, and the other tower desorbs and regenerates. The opening and closing of pneumatic valves are controlled by a program controller to make the two towers alternate and cycle continuously to produce high-quality oxygen.

Basic Structure:

- Air compressor: Inhales and pressurizes air to provide air with a certain pressure for the subsequent adsorption process.

- Compressed air purification system (refrigerated air dryer + filter): Cools the compressed air to reduce the air temperature, prevent the adsorbent from deteriorating in performance due to high temperature, and at the same time remove some moisture and impurities in the air.

- Air buffer tank: Plays a role in stabilizing air pressure and flow, ensuring that the air pressure and flow entering the adsorber are relatively stable and reducing the impact of fluctuations on the adsorption effect.

- Switching valve: Used to control the switching of air between different adsorption towers to realize the alternation of adsorption and desorption processes.

- Adsorber: Filled with adsorbents (such as zeolite molecular sieves), it is the core component for realizing the separation of nitrogen and oxygen.

- Oxygen process tank: Used to store and stabilize the produced oxygen to make the pressure and flow of oxygen output more stable.

Technical Characteristics:

- Easy operation: Stable operation, high degree of automation, can realize unmanned operation, reducing labor operation and management costs.

- Adjustable oxygen purity: According to user needs, the oxygen purity can be conveniently adjusted within a certain range (such as between 21% and 93±3%) to meet the oxygen purity requirements of different application scenarios.

- High efficiency and energy saving: Compared with the traditional cryogenic separation oxygen production method, the PSA oxygen generator has lower energy consumption and a fast start-up speed. It can reach a stable oxygen production state in a short time and is suitable for occasions with fluctuating oxygen demand.

- Compact equipment: The overall structure is relatively compact, with a small footprint and relatively flexible installation and layout, making it convenient for use in different places.